The Art of Milling at Grain Millers’ Specialized Facilities

September 18, 2020

For us, milling is more than a process–it’s an art. Let us take you on the journey.

Procurement

We buy directly from the farmers whenever possible. Before the oats even make it to our facility, we have already invested in helping our farmers grow the best possible crop. Our procurement strategy provides a dependable market for the farmer, gives them access to our direct delivery points and provides both parties with the opportunity to build the most important part of any business transaction—a strong, long-lasting relationship. Grain Millers’ crop scientists work with farmers to ensure that they’re growing the best oat variety for their environment, managing everything from soil testing to seed identification. Our free and voluntary Sustainable Grower Program helps farmers improve their operations, which in turn means our customers get an uncompromised quality of oats.

The Grain Millers difference happens because our passionate group of people make good things happen all along the way—from farm to table.

Cleaning

Oats are transported to our mills by rail and truck. Upon entering the mill, oats are immediately cleaned and sorted to remove any foreign material that made its way to the mill from the farm. In this process, oats pass through various types of equipment specifically designed to remove contaminants.

Dehulling

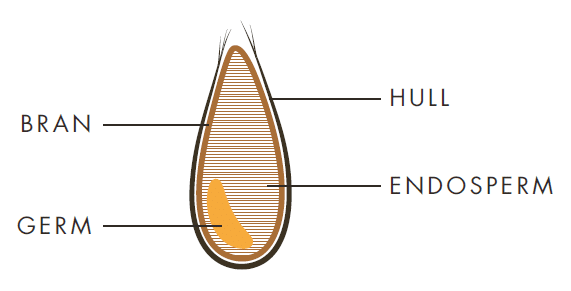

Here’s where the fun comes in: inside of our dehulling equipment, the oats are launched against a rubber ring which compresses the oat end to end and pops off the outer hull layer, leaving only the internal kernel known as a “groat” (the yummy part). Our mill operators are trained to balance throughput and dehulling speed, aiming for high efficiency of hull removal that doesn’t result in too many broken groats.

Kilning (It’s what makes the oats taste good)

Kilning, or running groat material through a steam-heated kiln, serves two purposes: Although it is primarily used to ensure shelf stability to neutralize the enzymes that lead to rancidity, it also adds that great traditional toasty oat flavor we are known for. Grain Millers has over thirty years of experience perfecting the art of time and temperature when it comes to the kilning of our oats, and that expertise is apparent in our finished products.

Separation and Flaking

After kilning, our freshly toasted groats are separated into whole oat groats and broken groats. The latter are used to make steel cut oats of various sizes, but we can also “cut” whole groats into steel cut, if needed. When we produce Certified Gluten-free oats, extra cleaning is performed to remove any traces of glutenous foreign grains such as wheat, barley, or rye. To learn more about Gluten-free oats, click here!

Next comes the flaking process, where the magic continues, during which the groats are rolled into specific products for our discerning customers.

Our operators know how to make specific adjustments to our equipment to meet all of our customers’ requirements everytime. Whole oat groats become either thick rolled or regular rolled oats, depending on specifications and flaker settings. Steel cut groats become quick cooking or instant oats. We have the ability to customize mill these products to produce various thicknesses, absorptions and particle sizes based on our customer’s demands.

At this stage, both types of groats can also be sent to the bran mill to become oat bran or whole oat flour, two products that remain favorites with our customers.

Testing and Packaging

Before packaging, we ensure that nothing compromises the quality and consistency of our products. At every stage of our validated system, our employees use Grain Millers’ customer-designed control screens that are specific to our unique processes. Our customized production software allows us to quickly access traceability info for every ton at a moment’s notice. Our on-site quality teams are the last line of defense between our mills and our customer’s products—this team takes their jobs very seriously. All our products are samples and tested to ensure they meet our customer’s specifications and expectations. This combination of the latest technology, internal process control and process data collection along with well-trained, experienced operators and lab techs make Grain Millers products—consistently delicious every time.

In the final step in the process, oat products are packaged into various retail and food service size packages up to our industrial sizes of 25 lb. bags, 50 lb. bags, totes (supersacks), and railcars or bulk trucks.

Our People

No part of the milling process would be what it is without the great people who work directly with farmers and keep our mills running 24/7. With plenty of reasons to stay with us for the long haul—from participating in producing healthy products, to plenty of opportunities for career growth—it’s no surprise that many of our employees have been with us for 20+ years. The dedication of our employees is what sets us apart, and our customers directly benefit from their high level of commitment and performance.

The Grain Millers difference happens because our passionate group of people make good things happen all along the way—from farm to table.

Email us or give us a call to get in contact with an oat expert!